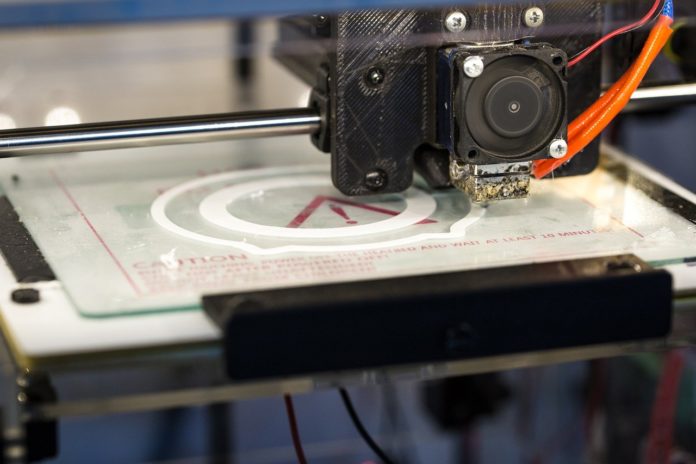

Students at Fontys College of Engineering have been able to use a robotic arm with a built-in 3D printer since February. The machine can print on a surface of 2 by 1.2 meters.

The machine can print with so-called polymeric materials. These are materials that are stronger, stiffer and lighter than steel. The aerospace and automotive industries usually use this material.

The printer is located at the Brainport Industries Campus (BIC). This is where third- and fourth-year students from the Mechanical Engineering and Mechatronics programs take their classes. The purchase of the printer allows the students to further specialize in the new printing technology.

Besides education, they shall use the printer for research projects. For example, Fontys will conduct research into lightweight vehicles. These types of vehicles are still mostly produced on a metal platform, which costs a relatively large amount of time and energy. Moreover, those metal bases are difficult to recycle. 3D-printed platforms should provide a circular basis for lightweight vehicles.

Fontys University of Applied Sciences Engineering was able to purchase the printer thanks to funds from the Brainport regional deal.

Source: www.studio040.nl

Translation: Chaitali Sengupta who also gives online classes for INBURGERING.