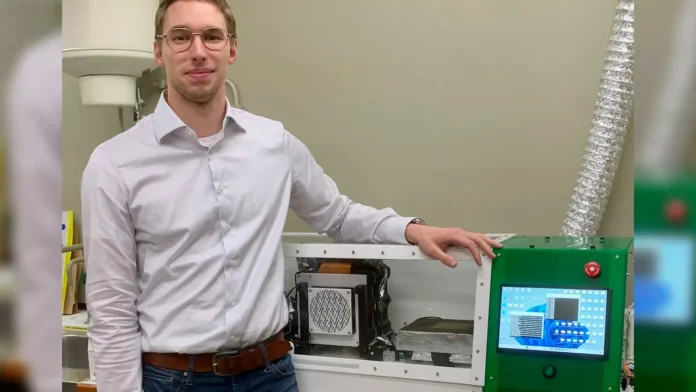

Veridis, Jeroen Glansdorp’s company, won one of the ten in Gerard & Anton Awards earlier this month. Using the scan technology Glansdorp developed, his company should ensure a more effective plastics recycling process. “The quality of recycled plastic is currently often very poor.

Amsterdam

Jeroen Glansdorp developed the idea to start a company with friends, all former fellow students of his. “We are all from Amsterdam, and attended Amsterdam University and the Vrije Universiteit. We all have a physics background and decided to find a solution for the often deplorable quality of recycled plastic”, says Glansdorp.

Brainport

Because the men did not know how to start a company with their idea, the ended up in Eindhoven. “We got into contact with High Tech XL, an organisation helping budding entrepeneurs to start up and develop a company. Thanks to them, the ball started rolling.”

“There are dozens of different kinds of plastic. Revycling firms separate these different kinds as well as they can. The separation is vital in order to turn the recycled plastic into a useful product, Glansdorp explains. “However, what is lacking at the moment is a way to check the quality of the recycled plastic.”

Damage

This lack of a reliable method poses a problem for recycling companies because a wrong composition can jam machines or even damage them. “When the plastic mix is wrong, it can jeopardise the next step in the manufacturing process. When a machine jams because of bad quality plastic, a company can easily lose thousands of euros. In the event of serious damage to the machine, the cost can run into hundreds of thousands”.

Veridis technology can scan the product, to establish its quality with 99 per cent accuracy. “Recycling companies can then prove that their product has a specifically defined quality.”

Investment round

At the moment Veridis works with a prototype from a location on the High Tech Campus. “Currently, a company takes a sample and sends it to us. We scan it and share the report with our client. Through an investment round we collected a million euros earlier this year. With that money we will build a scanner that we can place at the client’s company”, says Glansdorp